UV LED Modules

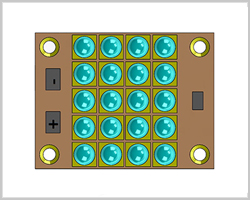

Model No.: ML6868-UVA-X

Wavelength: 365nm / 375nm / 395nm / 405nm

Power: 350W, 9600mA & 37V

Applications: Industrial UV curing lighting for 3D printing, coating, inking, coating, adhensives etc, 365nm and 395nm are the most popular.

UVA(365-405nm) LEDs are used for UV curing, nail polish dryer, grow lighting, trap insects, detector for checking counterfeit(such as jewelry, currency art etc.), photocatalyst and other UV sensitive materials through polymerization and so on. UV LED can improve existing process by enabling thinner, heat-sensitive substrates while reducing harmful byproducts such as ozone, and improving workplace safety. Additionally, UV LEDs turn on and off instantly, and utilize input power efficiently to enable lower operation costs over the application lifetime.

For high power ML6868 UV LED Modules, 365nm to 405nm are available, 350W super high power with 20pcs high power UV LED Chip 6868, 9600mA & 37V, 60degree beam angle for standard product, 30 / 90 / 120 degree beam angle available, providing our customers more solutions based on different designs and applications, for customized services, please kindly contact our sales for support.

| Model | Copper PCB Size | Wavelength | Power | If | Vf | LED Chip | Beam Angle |

|---|---|---|---|---|---|---|---|

| ML6868-UV-365 | 50* 38* 2.0mm | 360nm ~ 370nm | 350W | 9600mA | 36-39V | LB6868-UV-365 | 60 degree |

| ML6868-UV-375 | 50* 38* 2.0mm | 370nm ~ 380nm | 350W | 9600mA | 36-39V | LB6868-UV-375 | 60 degree |

| ML6868-UV-395 | 50* 38* 2.0mm | 390nm ~ 400nm | 350W | 9600mA | 36-39V | LB6868-UV-395 | 60 degree |

| ML6868-UV-405 | 50* 38* 2.0mm | 400nm ~ 410nm | 350W | 9600mA | 36-39V | LB6868-UV-405 | 60 degree |

Download |

|||||||

| PCB Design drawing for UV LED Module ML6868-UV | Date:2021-01-18 | ||||||

| PCB Size for UV LED Module ML6868-UV | Date:2021-01-18 | ||||||

UV curing refers to a special way in which coatings, inks and adhesives are cured or dried using “energy” from UV light sources, rather than conventional heat. In effect, the ultraviolet light spectrum in a UV lamp interacts with specially formulated chemistries to cure materials--typically more quickly, using less energy and thereby at lower cost than by other methods. In addition, UV is considered environmentally friendly since most of the solvents in inks, paints, adhesives and coatings can be eliminated.